Ribbon Blenders

MIXSYS Ribbon Blender offers precision and versatility across a range of materials and production scales.

Request a quote

Summary

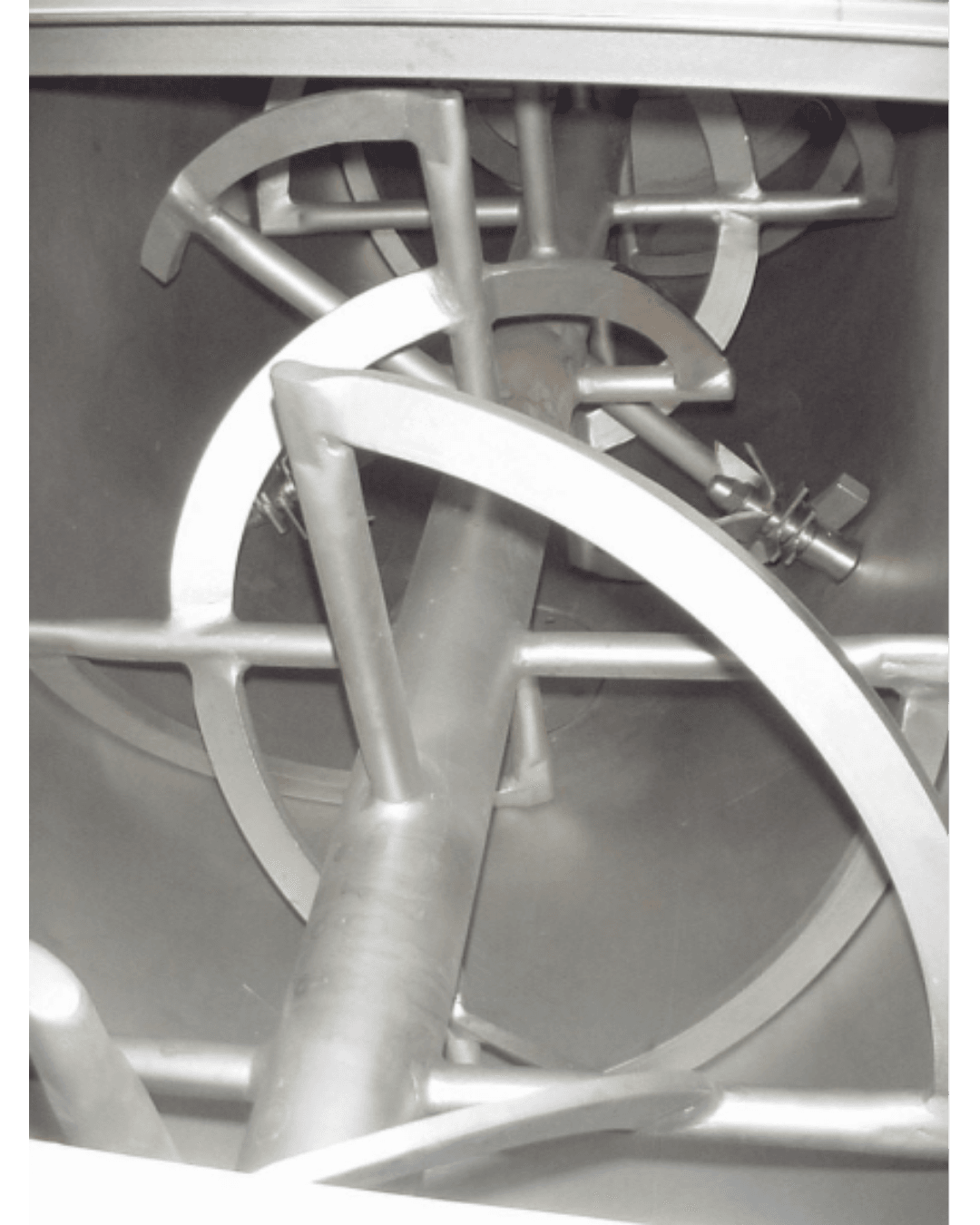

The MIXSYS Ribbon Blender is engineered to handle a variety of production processes efficiently, making it a versatile tool for industries requiring thorough and gentle mixing. It is particularly effective for handling fragile, heat-sensitive products. Through its innovative triple action agitator and counter-directional flow, the blender ensures rapid, homogeneous blending without generating excessive frictional heat, which could damage the product integrity.

This blender is ideal for a wide range of applications, from mixing powders, granules, and pastes to integrating liquids with solids reliably under controlled temperatures. It boasts not only a short processing time but also consistent high-quality outcomes with batch-to-batch repeatability. Its 'U' shaped chamber and four specially arranged ribbons contribute to its effective blending capability. Additionally, the blender is constructed from robust materials like AISI 304 and AISI 316 stainless steel, ensuring durability and compliance with food safety standards.

Furthermore, the MIXSYS Ribbon Blender is equipped with several operational features that enhance usability and maintenance. These include top and bottom doors designed for safety and convenience, rotor shafts with advanced sealing systems, and optional additions like pneumatic samplers and liquid injection systems. The availability of custom finishes and easy-access inspection doors with safety locks highlight its user-friendly and safety-oriented design. This makes the blender not only efficient in operation but also easy to maintain, meeting the needs of modern production environments.

Benefits

- Quick and homogeneous blending

- Suitable for fragile, heat-sensitive products

- Less frictional heat production

- Highly adaptable for different materials

- Ensured product integrity with gentle mixing

Features

Ideal for Various Production Processes

- Mixing of powders, granules, flakes, fibers, and pastes

- Wetting solids with one or more liquids

- Heating, cooling, and temperature control

- Keeping products in movement (stirred bunker)

Key Features

- Efficient mixing with short processing time

- Consistent high-quality mixing results

- Batch-to-batch repeatability

- Gentle mixing action preserves product integrity

- Minimal maintenance requirements

Technical Specifications

- Batch size from 3 cubic ft to 775 cubic ft.

- U-shaped mixing chamber design

- Four ribbons arranged in pairs for thorough blending

- Constructed from various materials including carbon steel and AISI 304