Specialty Chemicals

MIXSYS: Innovative Solutions in Specialty Chemicals

MIXSYS can revolutionize your specialty chemicals manufacturing. With cutting-edge process technology and reliable material handling equipment, we address the specific challenges of the chemical industry to improve safety, efficiency, and product quality. We offer comprehensive plant design—from raw material storage and conveying, through mixing, all the way to packaging. MIXSYS is your trusted process partner.

Why MIXSYS for Specialty Chemicals?

MIXSYS provides reliable, safe, and flexible solutions for specialty chemicals, ensuring precise processes and consistent products essential for top-quality manufacturing.

Key Offerings

Precision Mixing and Blending Systems:

Achieve exact chemical formulations with our high-accuracy mixers and blenders, designed to handle a variety of chemical properties safely.

Controlled Feeding Systems:

Precise ingredient handling to ensure consistent batch quality and composition.

Automated Batching Processes

Streamline your operations with automated systems that reduce manual errors and increase throughput.

Robust Conveying Solutions:

Durable equipment tailored to withstand harsh chemicals and reduce contamination risks.

Custom Automation and Control Solutions

Enhance your plant’s efficiency with our tailor-made control systems that allow for real-time monitoring and adjustments.

Project Highlight: Improved Thermo Paint Production—Covering Storage, Ingredient Feeding, Mixing, Bagging, and Robotic Palletizing Across Two Lines

Shown below are images of a newly installed turnkey system for a Thermo Paint Manufacturer in Texas, USA. This advanced plant is carefully engineered to streamline processes and boost efficiency in major, minor, and micro ingredient handling, dosing, conveying, batching, mixing, bagging, palletizing, and stretch hood operations.

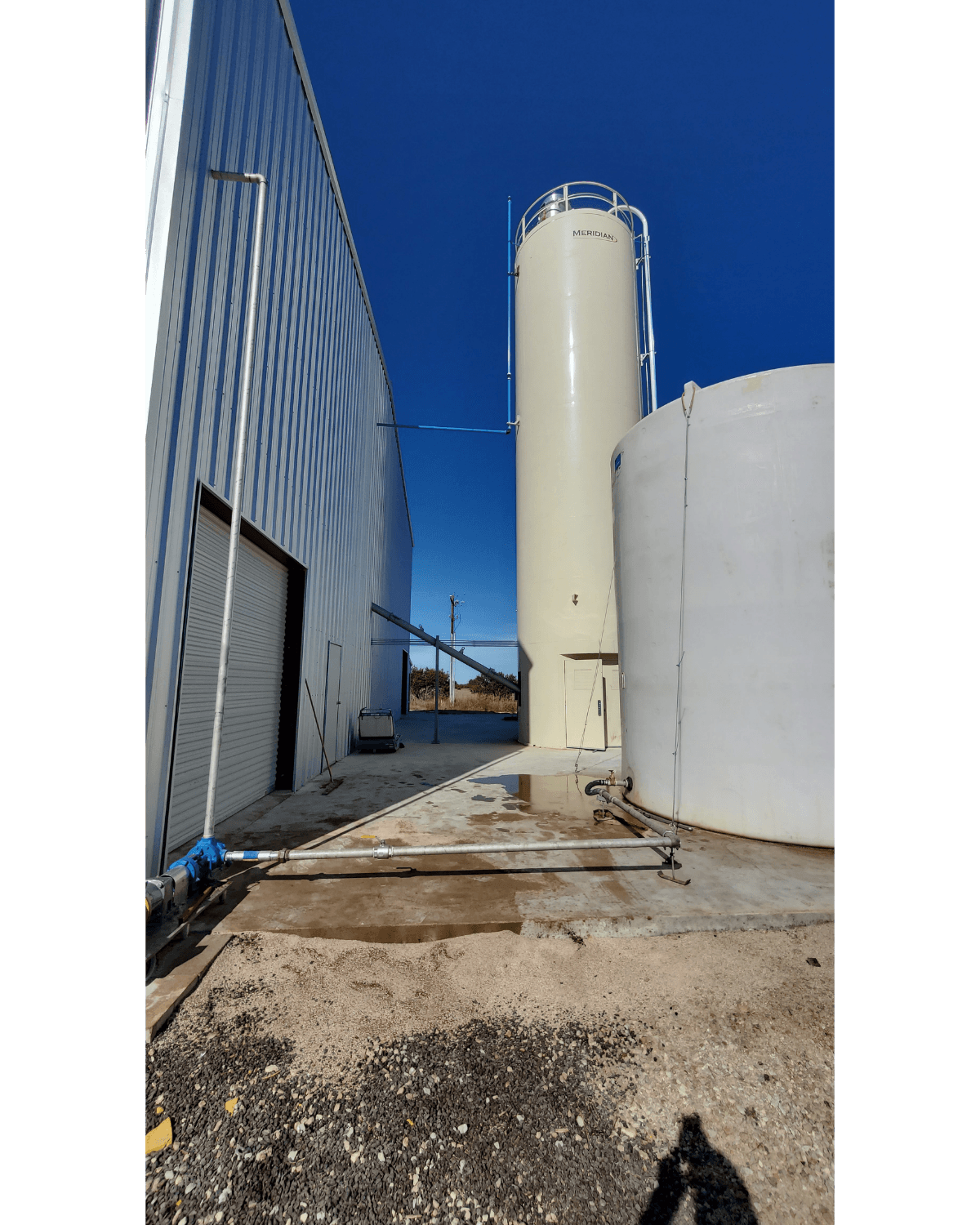

· Bulk Storage Silo and Castor Oil Storage with conveying and liquid pump dosing system.

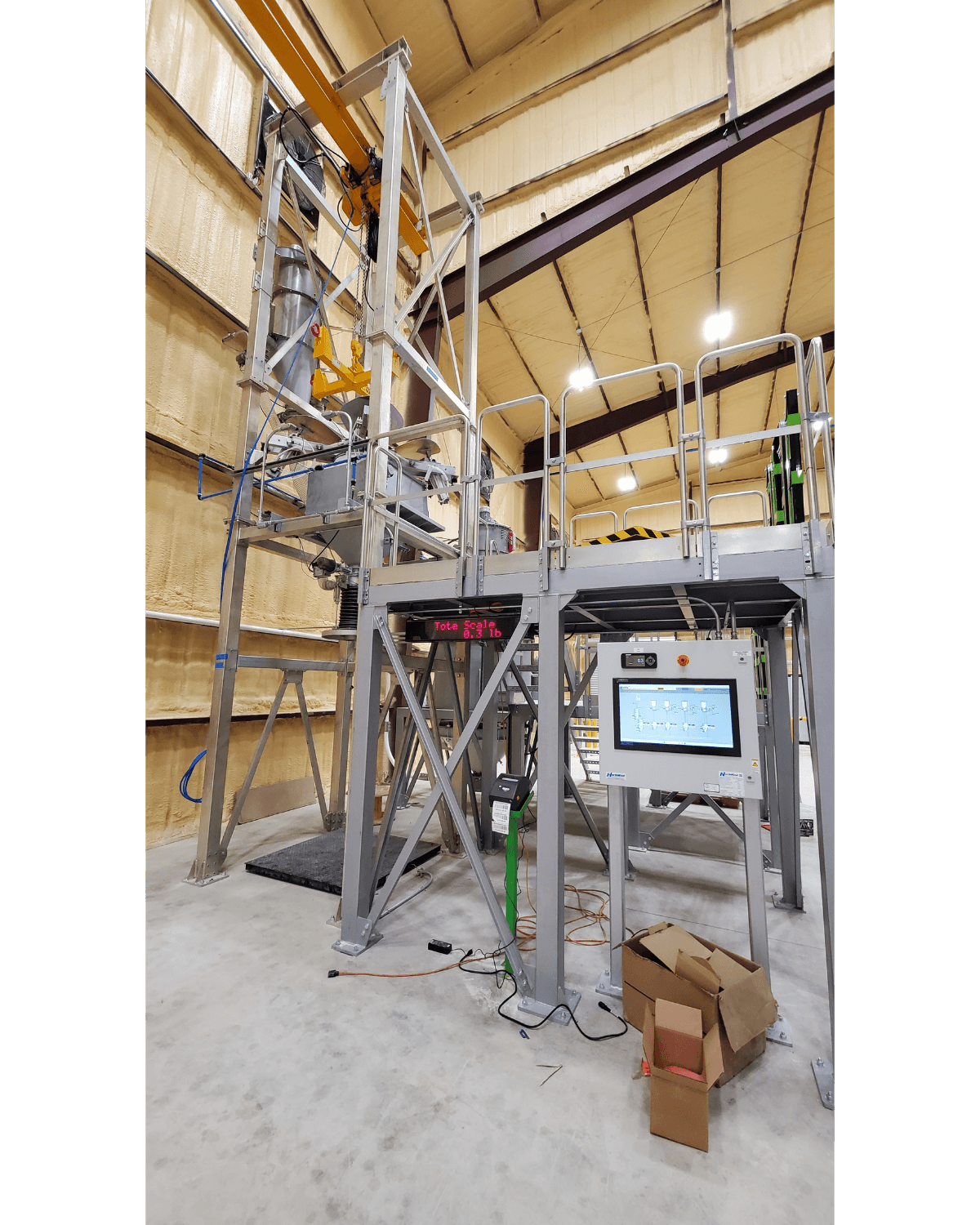

· Calcium Loss-n-weight dosing system

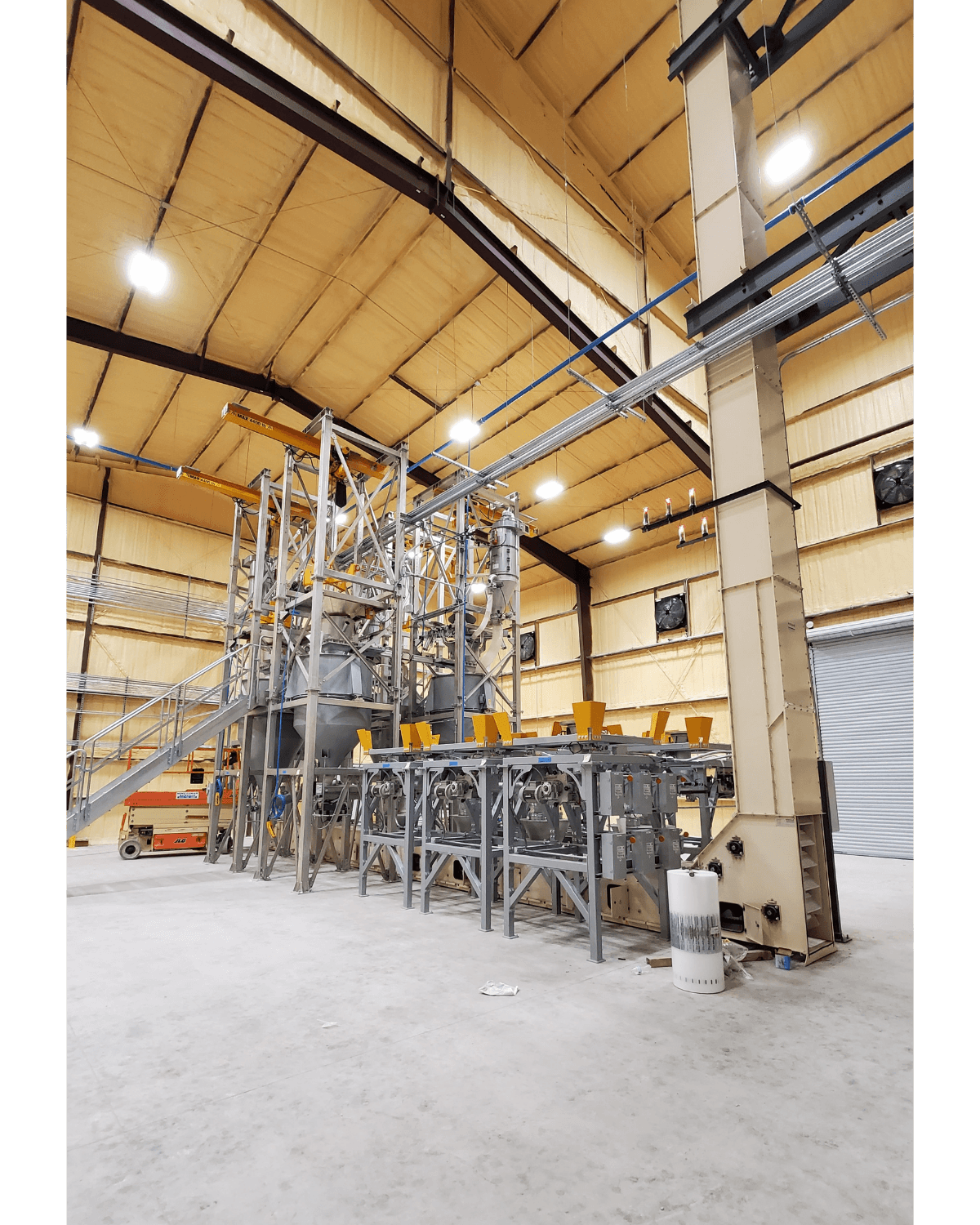

· Bulk bag unloaders (Minor Ingredient Feeding) with MixSys Clean-Connect for dust free connection from bulk bag spout to Weigh Hopper

· Mixsys Smart Ingredient Tote Ingredient Manage System w/ Quick Clean Screw system for cleaning between campaigns.

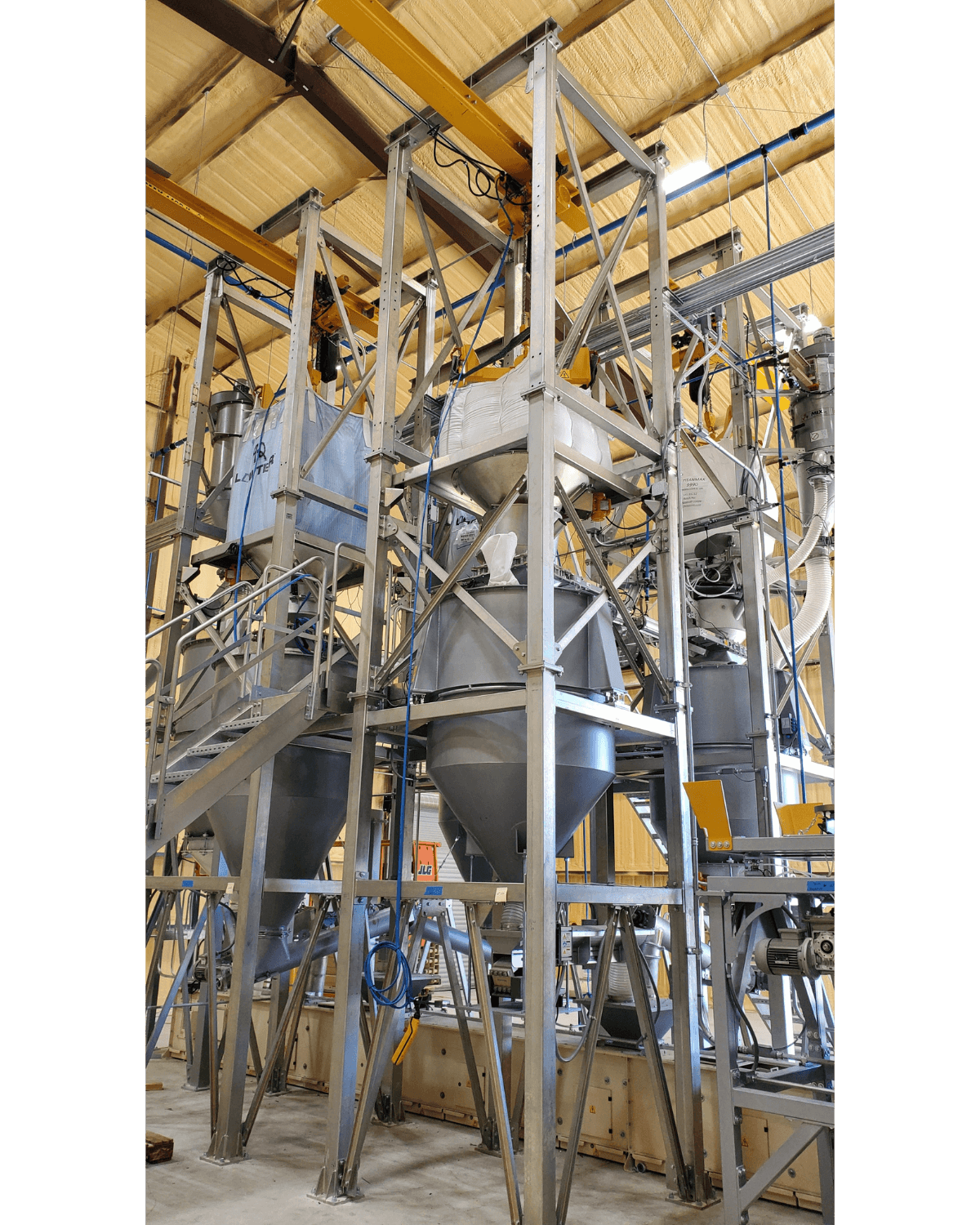

· Continuous ingredient conveying system using NERAK bucket conveying system to delivery to MIXSYS PLOWMIX – Mixers (Yellow and White Packaging Lines)

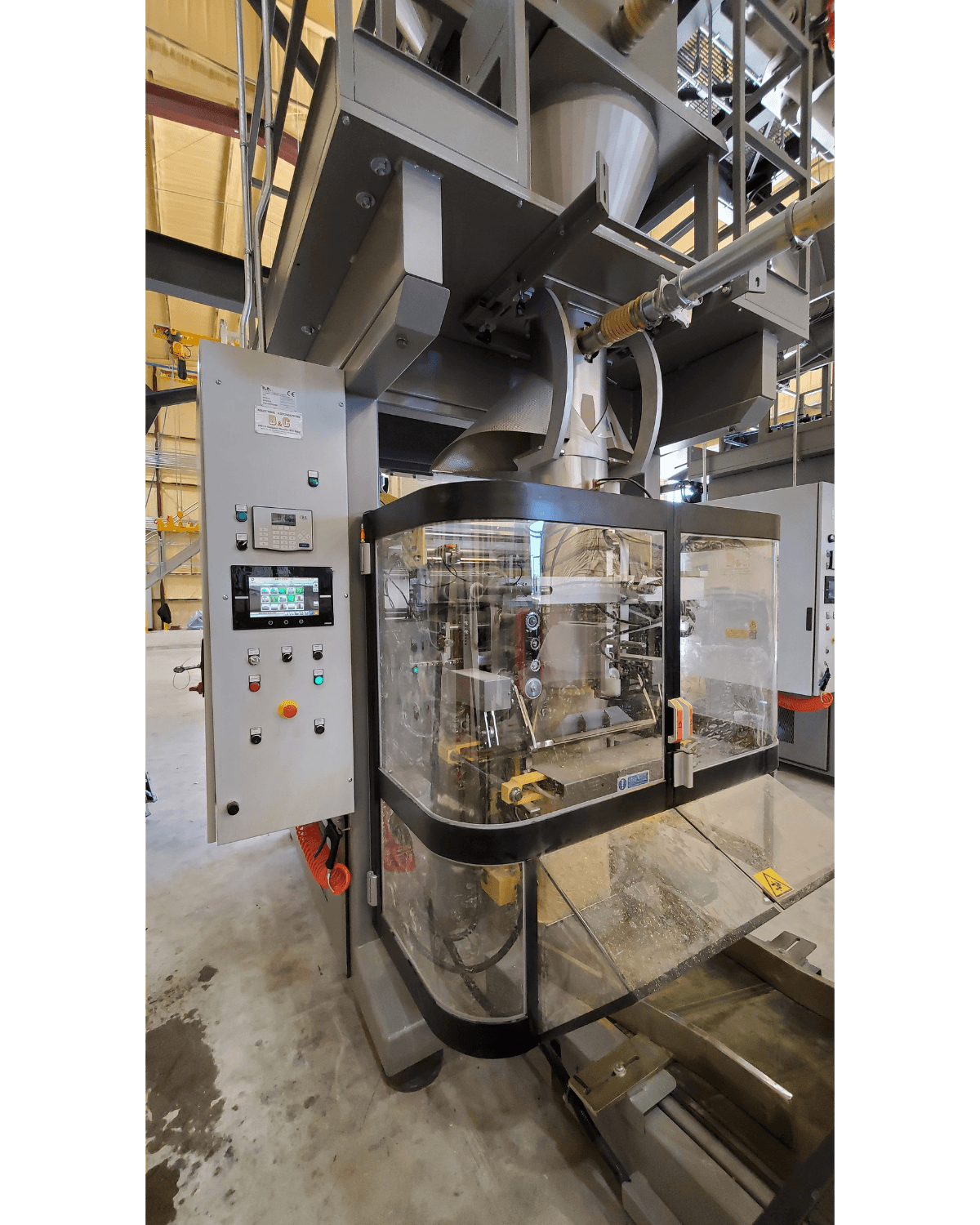

· MIXVFFS – Vertical Form Fill and Seal Dust free high speed bagging system.

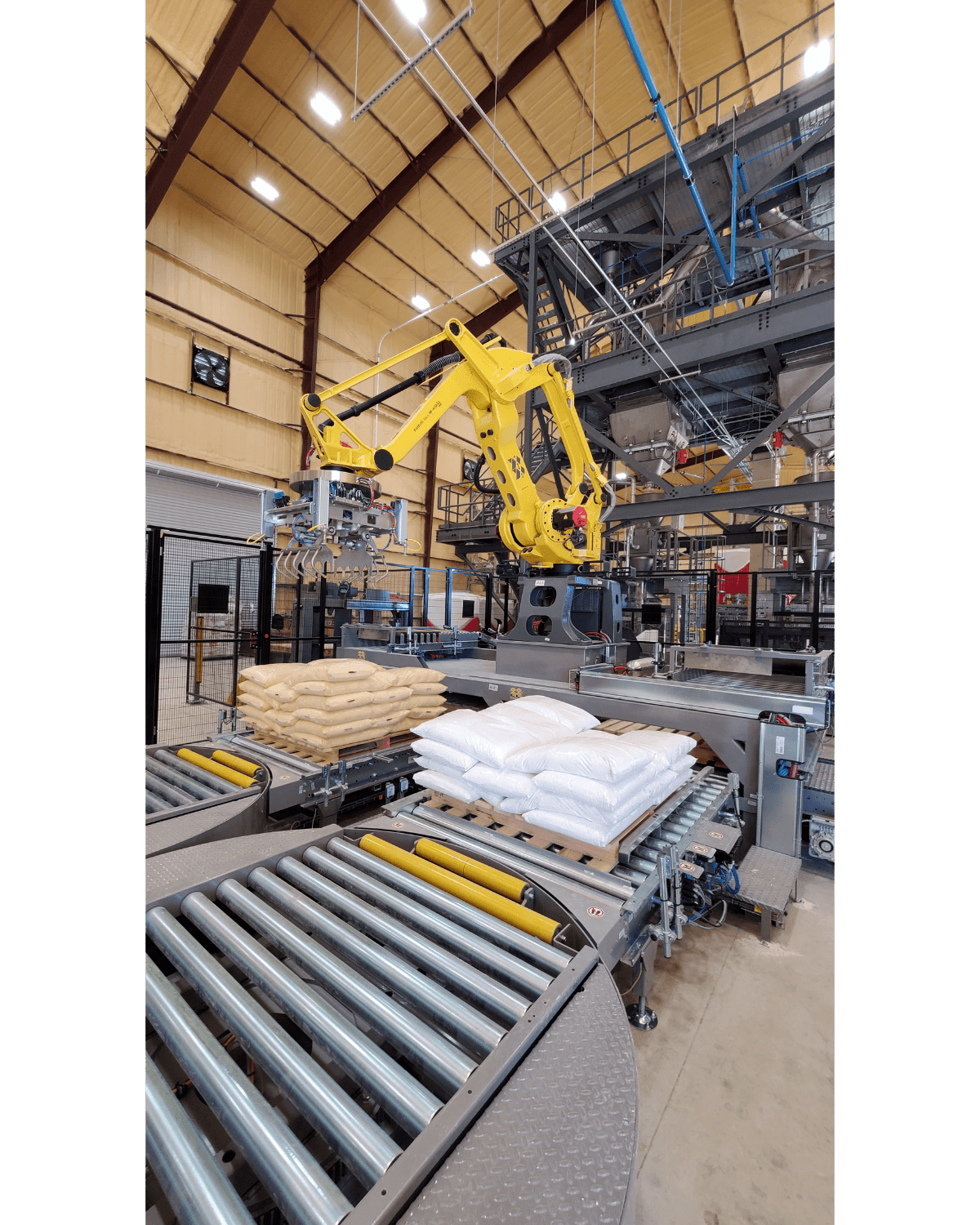

· Dual Line MIXFLEXBOT Robot Palletizing system with end of line Stretch Hood system for Pallet Stabilization and Product Protection.

Below are images of a newly installed turnkey system for a Thermo Paint Manufacturer located in Texas, USA. This state-of-the-art facility is designed to optimize workflows and enhance efficiency across all levels of ingredient handling, dosing, conveying, batching, mixing, bagging, palletizing, and stretch hood operations.

- The plant features bulk storage silos and castor oil storage equipped with conveyor systems and liquid pump dosing.

- It includes a calcium loss-in-weight dosing system.

- Bulk bag unloaders handle minor ingredients using the MixSys Clean-Connect feature, ensuring a dust-free transfer from bulk bag spouts to weigh hoppers.

- The Mixsys Smart Ingredient Tote Management System also comes with a Quick Clean Screw mechanism for easy cleaning between production campaigns.

- A continuous ingredient conveying setup utilizes the NERAK bucket conveyor to deliver materials directly to MIXSYS PLOWMIX mixers for the yellow and white packaging lines.

- The facility incorporates the MIXVFFS vertical form-fill-seal system for high-speed, dust-free bagging.

- Finally, dual-line MIXFLEXBOT robotic palletizers work alongside an end-of-line stretch hood system, stabilizing pallets and protecting products.