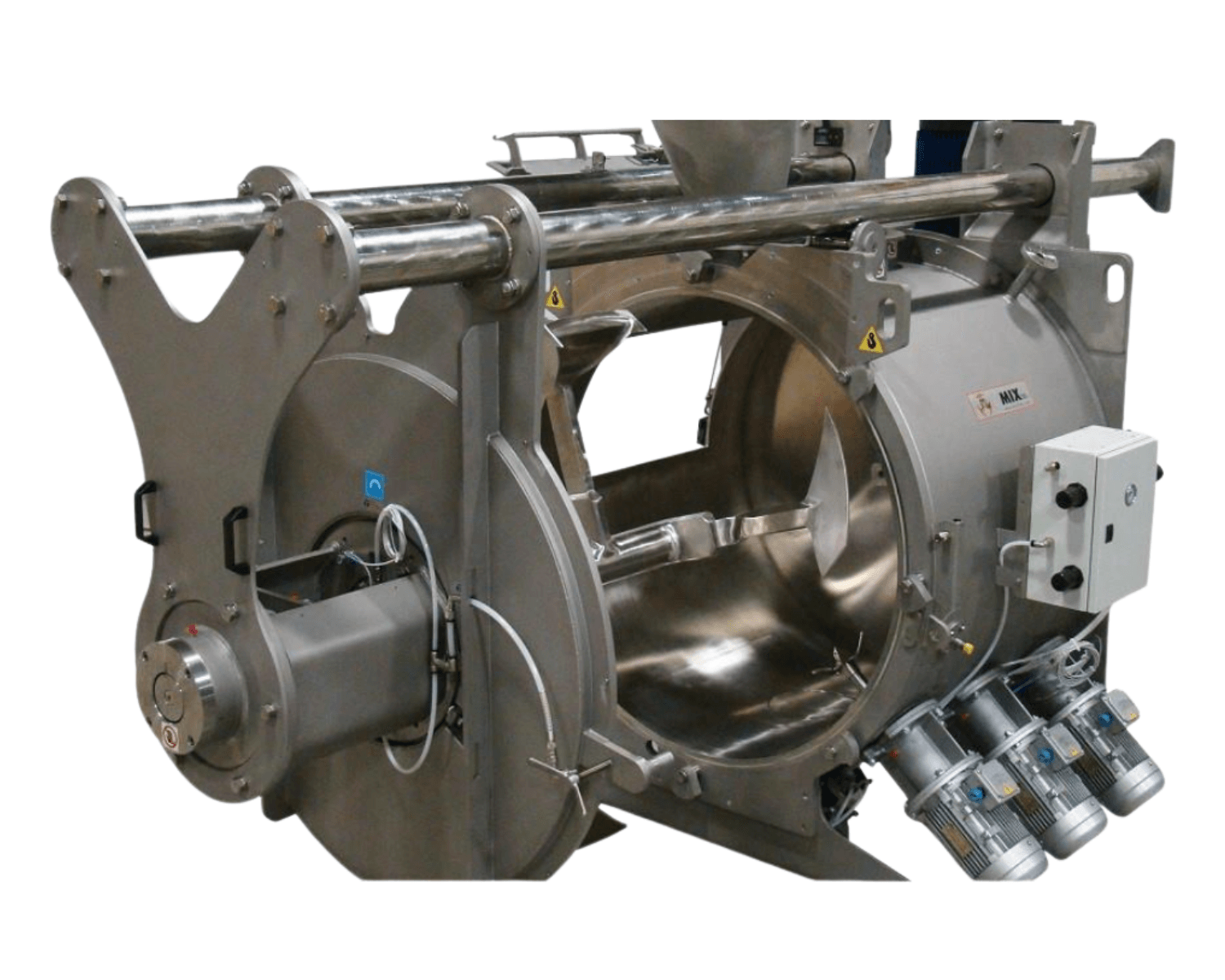

Extractashaft Mixer

The Extractashaft Mixer ensures uniform blending with top-notch efficiency and safety, suitable for diverse mixing needs.

Request a quote

Summary

The MIXSYS EXTRACTASHAFT MIXER is engineered for a broad spectrum of production needs, delivering high-quality and uniform distribution in the blending of diverse ingredients such as powders, granules, flakes, fibers, and pastes. It integrates capabilities that cater to various applications, including efficient wetting of solids, granulation by injecting binding liquids, and applying coat films onto powders by precision liquid injection, followed by additional powder.

In addition to its versatility, this mixer stands out for its performance; it guarantees extremely high mixing quality within a short duration, achieving batches with consistent results. The innovative design provides for a mixing ratio as precise as 1/100,000 with a coefficient of variation (CV) of ≤ 3%, emphasizing its accuracy and reliability for critical blending operations. Moreover, the EXTRACTASHAFT ensures every operation is simple, from maintenance to deep cleaning procedures.

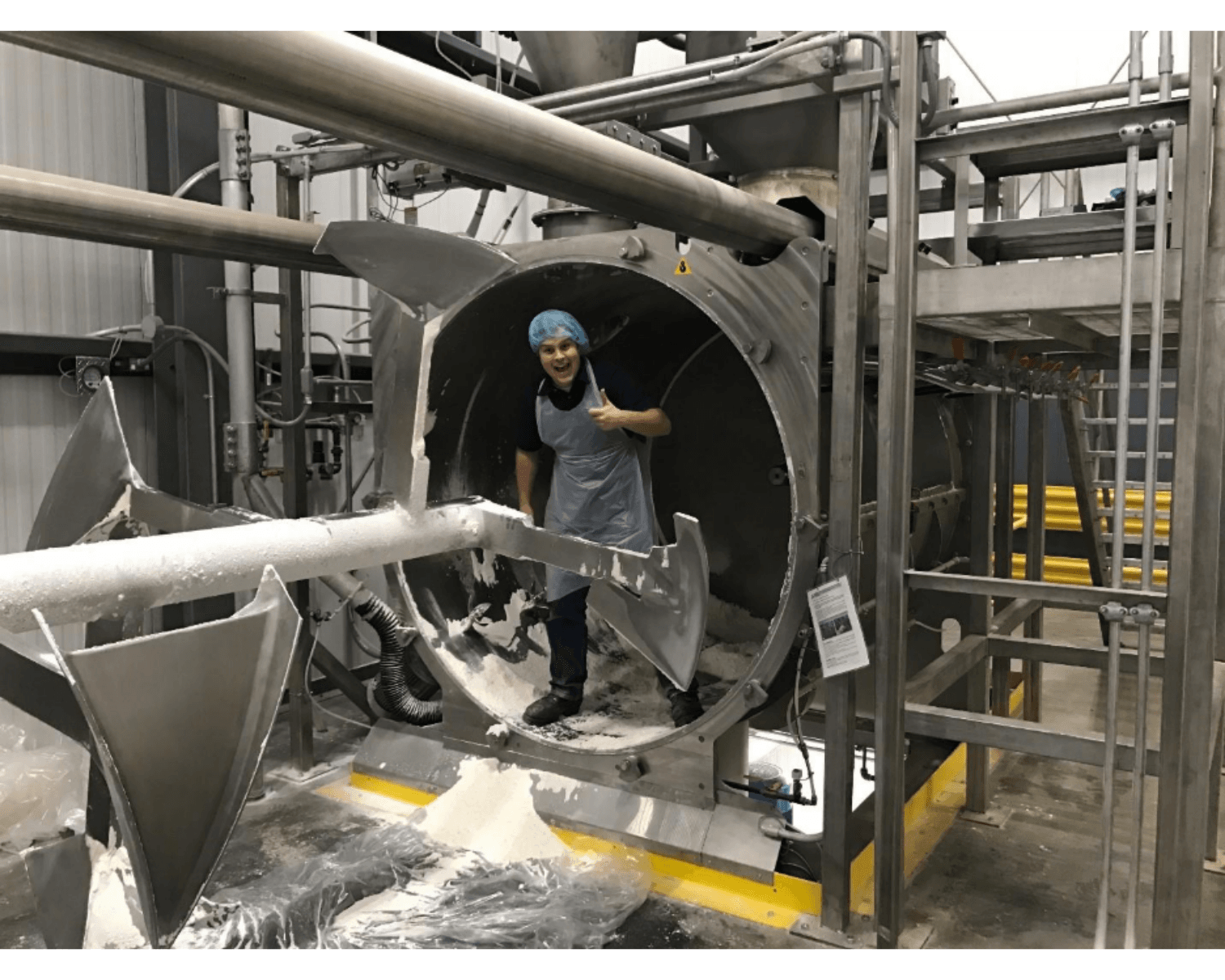

The mixer is constructed with user-centric features such as an extractable rotor shaft that facilitates full access to the mixing chamber, maximizing ease in maintenance and cleaning. Key enhancements include a variety of configurations in construction materials like carbon steel and different steel alloys (AISI 304, AISI 316, among others), ensuring robustness for various industrial demands. Further customization is offered in options like different finishes and configurations on elements contacting the products, adapting to specific industry regulations and requirements.

Benefits

- Enhanced mixing quality

- Rapid batch processing

- Easy maintenance and cleaning

- Versatile for various materials

- Optimized for safety and compliance

Features

Main Features

- Short mixing time

- Extremely high mixing quality

- Repeatable batch results

- Mixing ratio 1/100,000

- Coefficient of variation (CV): ≤ 3%

Technical Features

- Batch size from 3 cubic ft to 320 cubic ft

- Cylindrical mixing chamber design

- Variety of mixing tools available

- Material options from carbon steel to AISI 316Ti

- Full access to mixing chamber via extractable rotor shaft

Customization Options

- Compliance with food contact regulations

- Atex compliant models available

- Wolfram carbide-coated mixing tools

- Liquid injection system

- Pneumatic cleaning and sampler options